The difference between electrical service life and mechanical service life of relays

The life of an electromagnetic relay is calculated based on the number of times the contacts are opened and closed. Each time the contacts are opened and closed, their life is decreasing. Their service life mainly includes mechanical life and electrical life.

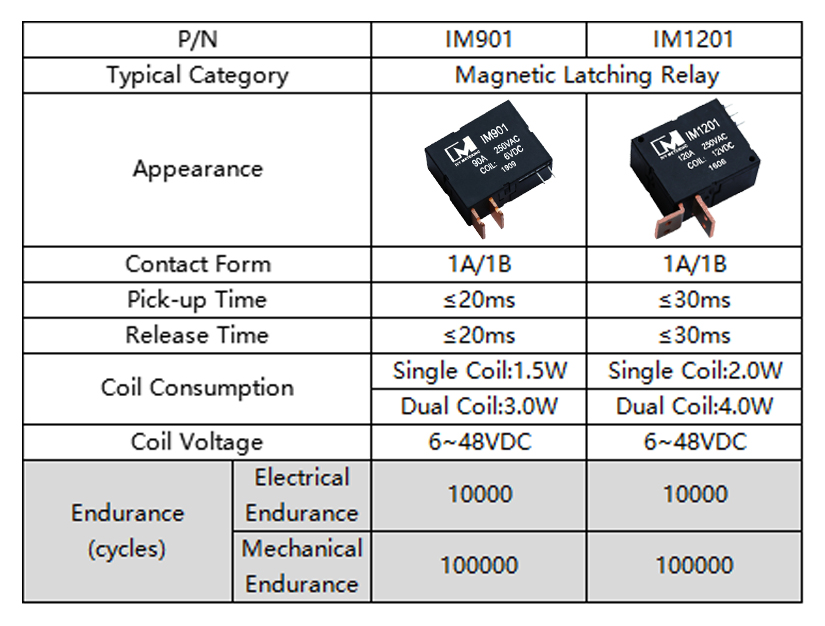

l Mechanical life: the number of cycles of no-load operation that the mechanical part of the relay can withstand before the mechanical parts need to be repaired or replaced.

l Electrical life: The number of load operation cycles for the mechanical part of the relay without repair or replacement of parts under specified normal working conditions.

Mechanical life refers to the number of times that the relay contacts can be opened and closed normally without being connected to the load. That is, the life of each action element on the relay. If one of the components is damaged, then the mechanical life is over!

The electrical life refers to the number of actions of the contact after it is loaded. Because the contact is closed and disconnected, there will be spark ablation and wear, so the material of the contact also determines the electrical life of the relay to a certain extent. In addition, the coil quality also affects the electrical life, and the stroke size (overtravel) of the moving contact will also affect the electrical life. In short, the main difference between electrical life and mechanical life of electrical appliances is: no-load operation is mechanical life, and load operation is electrical life.

Generally, the mechanical life is 100,000 times, and the electrical life is 10,000 times. The mechanical life of most relays is longer than the electrical life, and the mechanical life can basically be reached. Usually, the relay is damaged before the mechanical life is reached. It is because the electrical life has come, so if you simply pay attention to the mechanical life, this is actually meaningless, because your relay cannot be completely unloaded.

Choosing a long-life and durable relay is very important to the equipment. Compared with other relays, IVY machines pay more attention to the quality of the contacts. The AgSnO2 material we use contains higher silver content and is more durable. At the same time, our products have passed IEC62055-31 UC2/UC3 C3 service life tests. Therefore, IVY has become a leader in the global relay industry with its excellent performance and excellent quality. For more information, please click: https://www.ivy-metering.com/