What is Difference Between Type A+DC 6mA and Type B Sensor for EV Charger?

1. Technical principles and detection range differences

Type A+DC 6mA sensor

Detection capability: mainly for AC, pulsating DC (jumping DC) and half-wave AC leakage current, and additional detection of 6mA smooth DC.

Technical background: As a transitional solution, superimposed DC detection makes up for the defect that Type A sensor may fail to provide AC leakage protection due to magnetic ring saturation in smooth DC scenarios.

Limitations: only covers part of the DC leakage current (such as 6mA threshold), and cannot fully monitor complex DC components (such as intermittent DC, high-frequency mixed current).

Type B sensor

Detection capability: fully covers AC, pulsating DC, half-wave AC, smooth DC and intermittent DC, and supports all types of leakage current monitoring.

Technical advantages: adopts more advanced fluxgate or magnetic modulation principles, has strong anti-interference ability, can accurately identify complex current components, and avoid false alarms or missed alarms.

Application scenarios: suitable for high-power charging (such as mode 4), complex topology circuits and areas with strict safety standards (such as Europe).

II. National Standards and Compliance Requirements

China National Standard (GB/T 18487-2023)

Implementation time: Released in 2023, fully enforced in 2025.

Core requirements:

Charging piles must support Type A leakage current protection (AC 30mA) and add a smooth DC detection function of 6mA and above.

Old charging piles that are only certified for Type A must be upgraded before 2025, otherwise the certification will be revoked.

Standard significance: By forcing 6mA DC detection, promote the popularization of Type B technology and align with international standards (IEC 61851).

International standards (IEC 62752/IEC 61851)

IEC 62752 (Mode 2 charging): Requires the use of Type B sensors to cover all types of leakage current.

IEC 61851 (Overall safety): Clearly stipulates that leakage protection must include AC, DC and mixed currents, and recommends Type B sensors as best practices.

European market implementation: Tesla and other manufacturers need to build in Type B sensors in charging piles or rely on external Type B circuit breakers to meet grid connection specifications.

Certification and implementation points

China: CQC certification requires companies to complete the adaptation of the new national standard before 2025, otherwise the old certification will be revoked.

Europe and the United States: Type B sensors have become standard for export charging piles, and some markets (such as Germany) require Type B circuit breakers for mode 4 charging.

III. Selection recommendations and future trends

Selection basis:

Domestic projects: Type A+ sensors or Type B sensors that support 6mA DC detection are preferred to meet the new national standard.

Export or high-demand scenarios: Directly use Type B sensors to avoid repeated upgrades.

Technology trends:

With the increase in charging pile power (such as 800V high-voltage platform) and the complexity of circuits, Type B sensors will become mainstream.

Integrated solutions (such as Type B sensors + MCU control) can flexibly customize protection logic and reduce costs.

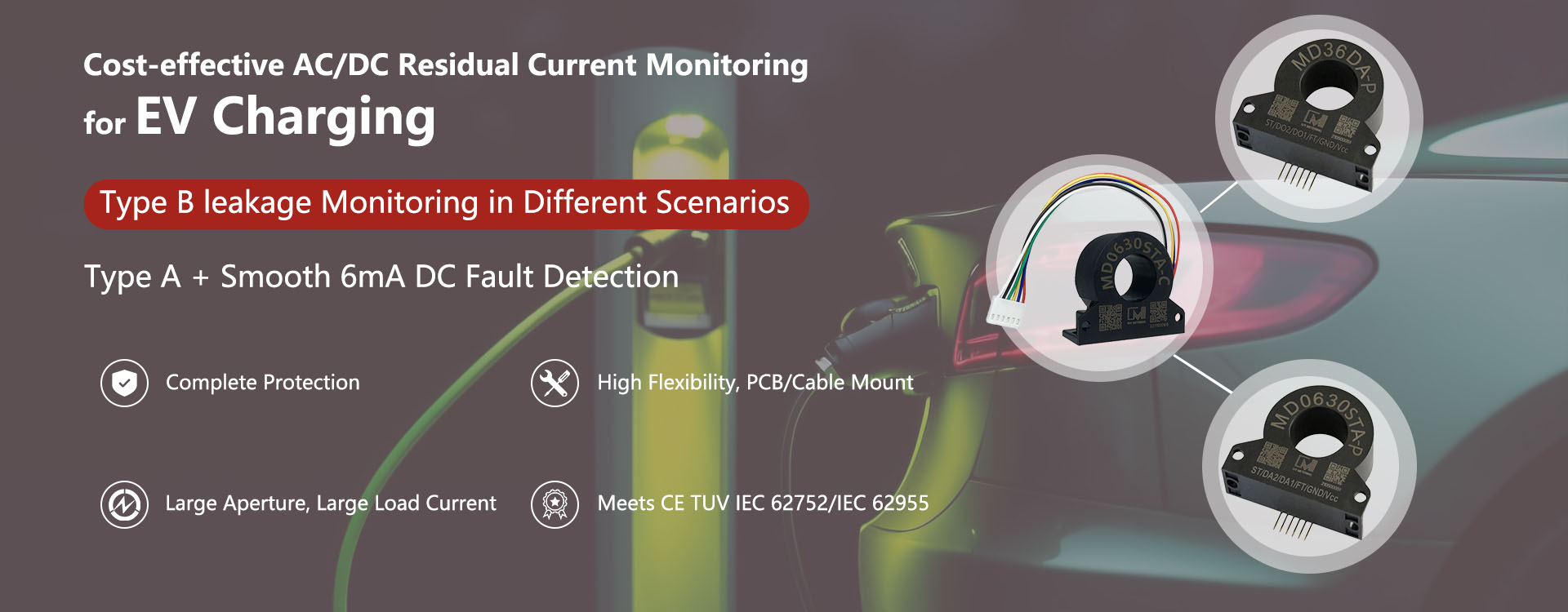

The advantage of Type B residual current sensor over Type A+6mA residual current sensor is that it can detect and identify both AC leakage current and DC leakage current, providing more comprehensive safety protection. Type B residual current sensor is designed according to the standards of the International Electrotechnical Commission (IEC) and can accurately monitor the leakage of the AC grid itself and the small DC leakage that may be generated by the battery management system (BMS). This comprehensive monitoring capability makes Type B sensor more advantageous in situations where high safety standards are required, such as electric vehicle charging systems. It not only protects personal safety, but also prevents fire hazards caused by continuous ground fault current.

In contrast, Type A+6 residual current sensor, where Type A refers to traditional leakage protection devices that can only detect AC leakage, adds additional monitoring functions for DC leakage (such as 6mA level) on this basis. Although Type A+6mA sensor also has a certain DC leakage detection capability, its design and application are often targeted at specific markets or early charging pile designs, and may be inferior to Type B sensor in comprehensiveness and accuracy. In addition, type B residual current sensors have gradually become mainstream in the market, especially in the context of the continuous optimization and upgrading of the new energy vehicle industry and the rapid development of the charging pile industry, the safety reliability and cost-effectiveness of type B sensors are more prominent. In summary, type B residual current sensors have more obvious advantages than type A+6 sensors in terms of monitoring capabilities, safety standards and market adaptability.