Wireless CT Current Sensor Empowering Efficient Energy Management

In the invisible world of electricity, there is a silent guardian that, in a way we cannot perceive, quietly ensures the stability and safety of the power system. This is the wireless current sensor—a revolutionary current monitoring solution. Unlike traditional monitoring equipment, it eliminates the need for cumbersome wiring, using wireless technology to achieve real-time, accurate current monitoring.

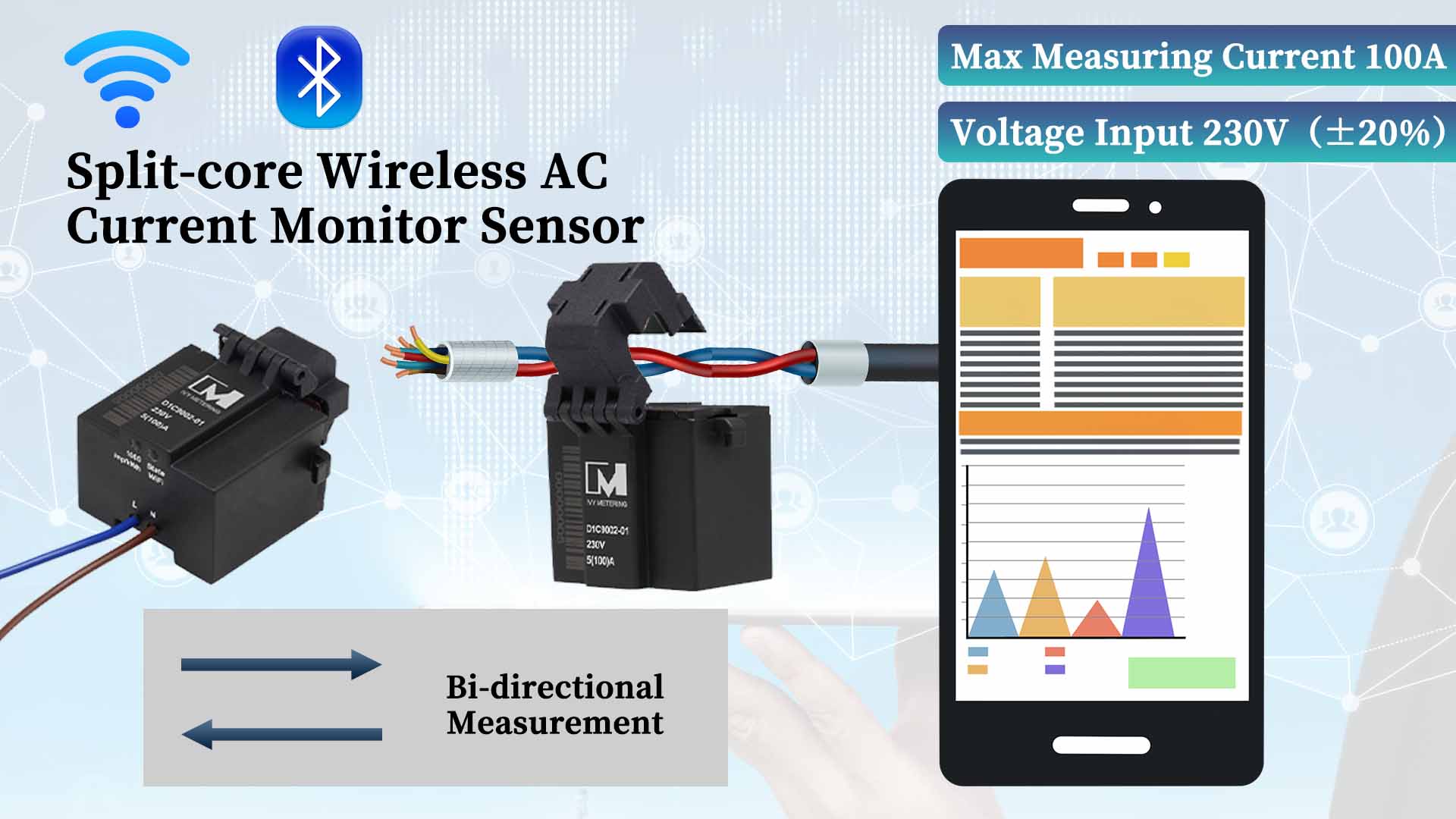

Wireless current sensors are typically clipped around conductors or connected in series with circuits to measure current, and then transmit the data wirelessly (Wi-Fi, Bluetooth, cellular networks, LoRaWAN) to a gateway or cloud platform for analysis. The core of the wireless current sensor lies in its unique electromagnetic induction principle. When current flows through a conductor, it generates a magnetic field around it. The sensor captures this magnetic field change, converts it into an electrical signal, and thus measures the current.

Key Advantages

Wireless Connectivity: Supports WiFi, Bluetooth, and Lorawan etc communication for convenient data transfer, eliminating the need for additional wiring.

Split-Core Design: The sensor uses a clamp-on current transformer (CT clamp) structure, which can be directly attached to existing cables, simplifying the installation process.

Real-time Monitoring: Users can view electrical parameters such as voltage, current, power, power factor, frequency, and active energy anytime, anywhere via the network.

Bidirectional Measurement: Capable of measuring both forward and reverse current and power, suitable for applications such as solar photovoltaic systems.

Wide Range of Applications: Suitable for energy management, smart buildings, industrial equipment monitoring, and electric vehicle charging station metering.

High Accuracy: Features high accuracy and stable performance.

Data Reporting: Data can be reported to a cloud platform.

Wireless current sensors offer advantages such as easy installation, improved safety, and reduced wiring complexity, and are widely used in various industries.

Energy Monitoring and Management: Used in commercial and industrial environments for energy auditing, tracking equipment energy consumption, and helping businesses reduce energy waste and comply with sustainability goals.

Building Automation and Smart Grids: Integrated into building automation systems (BAS) or smart grid technologies to enable load balancing, demand response programs, and automated control (e.g., shutting down systems when high current is detected).

Renewable Energy Systems: Used to monitor the flow of electrical energy from generation to the grid in systems such as solar power plants or wind farms.

IVY Metering manufactures a range of smart current sensors (such as model D1C9002-01 and D1C9002-02) for real-time monitoring of current and energy consumption. These sensors primarily utilize a split-core (clamp-on) design, facilitating installation without interrupting existing wiring. The devices transmit data via WiFi to a cloud platform and can be used in various applications, including smart homes, industrial automation, and electric vehicle charging stations.

With the continuous development of Internet of Things technology, wireless current sensors are gradually integrating into every corner of smart cities. Combined with big data, cloud computing, and other technologies, they are building a more intelligent and efficient power ecosystem for us.